Sàn nhẹ Ubot là sàn phẳng không dầm vượt nhịp cũng như chịu được trọng tải lớn, là giải pháp xanh trong xây dựng hiện nay.

Đối với một quốc gia, xây dựng luôn là ngành đóng vai trò kinh tế chủ chốt trong quá trình phát triển kinh tế – xã hội, tạo ra điều kiện cơ sở vật chất cơ bản cho sự phát triển. Tuy nhiên, ngành xây dựng luôn đi đôi với vấn đề môi trường khi là ngành tiêu tốn nhiều năng lượng và ảnh hưởng nhiều đến môi trường tự nhiên. Vì thế sàn nhẹ Ubot ra đời mở ra một hướng đi mới tạo sự biến đổi lớn cho ngành.

Vấn đề môi trường trong ngành xây dựng ngày nay

Việc tiến hành xây dựng một công trình đồng nghĩa với việc tiêu thụ và sử dụng một lượng đáng kể các nguồn năng lượng và tài nguyên môi trường, đồng thời tạo ra chất thải và khí độc gây ảnh hưởng đến môi trường sinh sống.

Do nhu cầu về lựa chọn xây dựng bền vững hơn tăng, “xây dựng xanh” ngày càng trở thành một xu hướng đáng quan tâm và đang dần thay đổi các phương án xây dựng truyền thống trong thị trường xây dựng tại Việt Nam và quốc tế.

Tại Hoa Kỳ, các tòa nhà được xây dựng theo tiêu chuẩn xanh đã được chứng nhận đã phát thải CO2 thấp hơn 34% so với các công trình khác, tiêu thụ nước và năng lượng ít hơn 25% và giảm đến 80 triệu tấn chất thải đến các bãi chôn lấp mỗi năm.

Ảnh hưởng của các dự án xây dựng đến môi trường đang là vấn đề nhức nhối trong xã hội ngày nay. Đối tượng bị ảnh hưởng nhiều nhất là môi trường không khí do các chất bụi bẩn được sinh ra trong quá trình thi công, giải phóng mặt bằng, san lấp, vận chuyển nguyên vật liệu. Bên cạnh đó, quá trình trộn vôi, vữa, rửa thiết bị máy móc làm ảnh hưởng một phần đến môi trường nước.

Ngoài ra, ô nhiễm về chất thải rắn (xi măng, thép, bê tông) cũng như ô nhiễm tiếng ồn cũng là trách nhiệm cần giải quyết của mỗi công trình xây dựng, nhất là với những công trình có quy mô lớn.

Nhận thức được vấn đề tiêu thụ vật liệu và năng lượng của ngành xây dựng, rất nhiều nước trên thế giới đã ban hành các quy chuẩn về “công trình xanh” nhằm hướng tới mục tiêu tiết kiệm năng lượng và tái chế, sử dụng hợp lý vật liệu xây dựng. Bộ xây dựng Việt Nam cho rằng nước ta nên hội nhập những tiêu chuẩn của thế giới để áp dụng vào Việt Nam.

Bên cạnh đó, Việt Nam được khuyến nghị cải thiện công tác quản lý chất thải rắn khi tỷ lệ trung bình 30% chất thải rắn bị thải ra môi trường xung quanh. Vì vậy, giảm thiểu chất thải rắn đồng thời mở rộng các khu xử lý chất thải công nghiệp là thực sự cần thiết.

Ubot – giải pháp xây dựng thế hệ mới hướng tới “công trình xanh”

Trước khi tìm hiểu về Ubot, chúng ta sẽ tìm hiểu khái niệm về “công trình xanh”. Khái niệm Công trình Xanh do Hội đồng Công trình Xanh Hoa Kỳ – gọi tắt là USGBC đưa ra, nhằm nói đến những công trình đạt được hiệu quả cao trong sử dụng năng lượng và vật liệu, giảm thiểu các tác động xấu tới môi trường; đồng thời được thiết kế để có thể hạn chế tối đa những tác động không tốt của môi trường xây dựng tới sức khỏe con người và môi trường tự nhiên.

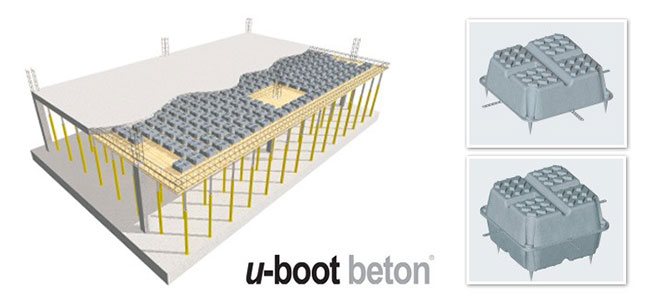

Được sáng chế và phát triển bởi tập đoàn xây dựng lớn từ Italia – Daliform, Ubot là giải pháp công nghệ xanh tiêu biểu được sử dụng trong móng bè và kết cấu sàn. Kể từ năm 2001, hàng nghìn công trình xanh lớn nhỏ trên khắp thế giới, đặc biệt ở nhiều nước như Pháp, Ý, Brazil đã được ứng dụng công nghệ sàn Ubot trong xây dựng và kiến tạo.

Ngày nay, Ubot ngày càng trở nên phổ biến hơn nữa nhờ những hiệu quả về mặt kinh tế cũng như môi trường mà giải pháp này mang lại cho ngành xây dựng. Sản phẩm Ubot được chuyển giao công nghệ bởi LPC từ tập đoàn nổi tiếng Daliform từ năm 2012, với tên rút gọn tại Việt Nam là sàn nhẹ Ubot.

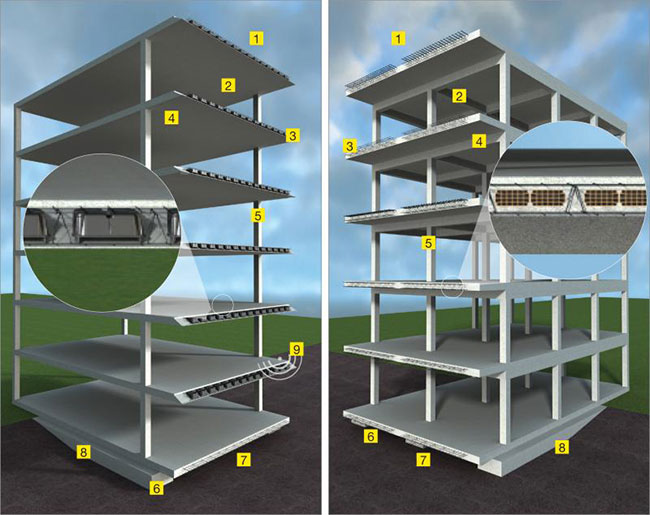

Ubot là hộp cốp pha bằng nhựa polypropylen tái chế được sử dụng để tạo nên sàn phẳng không dầm vượt nhịp lớn. So với các sàn beton cốt thép thông thường, Ubot có cấu tạo đặc biệt với 4 chân hình côn và phụ kiện liên kết giúp tạo ra một hệ thống dầm vuông góc nằm giữa lớp sàn bê tông trên và dưới, do vậy giảm được lượng bê tông và thép sử dụng.

Bên cạnh đó, việc sử dụng sàn nhẹ Ubot còn giúp cho việc giảm tải trọng xuống sàn, từ đó số cột cần sử dụng được giảm xuống. Sử dụng ít thép và bê tông hơn góp phần làm giảm lượng chất thải rắn, giảm ảnh hưởng tới môi trường xung quanh.

Ngoài ra, khi so sánh 2 công trình có cùng chiều cao hay số tầng, Ubot có trọng lượng nhẹ hơn dầm sàn bê tông thông thường giúp móng chịu tải trọng ít hơn, do vậy giảm công tác đào đất trong xây dựng, hạn chế việc làm ô nhiễm môi trường đất.

Việc lắp đặt Ubot là hoàn toàn thủ công, linh hoạt và nhanh chóng, không đòi hỏi cao về các phương tiện vận chuyển phức tạp. Vì vậy lượng máy móc và nhân công khi thi công sàn Ubot là ít hơn so với công tác thi công sàn thông thường. Sự di chuyển và vận hành máy móc được giảm bớt góp phần giảm ô nhiễm tiếng ồn xung quanh công trình xây dựng.

Ubot đã đạt được chứng nhận CCA về bảo vệ môi trường, chứng chỉ chứng minh Ubot không có chất nguy hiểm trong thành phần, không có sự phát xạ chất độc trong suốt vòng đời sản phẩm và quá trình thi công, đảm bảo sức khỏe cho người lao động (người sản xuất và lắp đặt) cũng như những người sử dụng công trình (người sống trong khu nhà) và thân thiện với môi trường nói chung.

Các công trình xây dựng với sàn nhẹ Ubot trên thế giới, bao gồm cả Việt Nam đã được chứng nhận là công trình xanh với kết quả đo lường giảm đáng kể khí thải nhà kính (CO2) và tiêu thụ năng lượng trong quá trình xây dựng. Bên cạnh đó, công trình Ubot có tuổi thọ vượt trội so với các công trình xây dựng truyền thống thông qua việc không bị ảnh hưởng nhiều từ những tác động tiêu cực từ môi trường và khí hậu.

Nhìn một cách toàn diện, việc sử dụng Ubot trong thi công xây dựng góp phần thực hiện trách nhiệm của ngành xây dựng đối với vấn đề môi trường, giảm thiểu tối đa ảnh hưởng tới môi trường tự nhiên và khu vực xung quanh công trình. Hơn thế nữa, Ubot là giải pháp đem lại giá trị dài hạn cho công trình, chất lượng bền vững không chỉ là 10 hay 20 năm mà lên tới 50-60 năm, là xu thế trên thế giới nói chung và Việt Nam nói riêng.

Nguồn: https://lpc.vn